| g e n u i n e i d e a s | ||||||

|

|

|

|

|

|

|

| home | art and science |

writings | biography | food | inventions | search |

| dry as a bone | ||||||||||||||||||||

|

Jul 2013 Humidity plays an under appreciated role in cooking. Low levels of humidity are essential to drying beef into jerky, or plums into prunes. High levels are needed to retain meat juices while pre-heating a hamburger before the "reverse sear", or cooking a chicken breast. In a barbecue smoker, humidity encourages collagen to convert to slippery gelatin before the meat dries out. And steam is the the key to forming the explosively crispy crust that defines a great baguette. Few recipes discuss humidity because, well, your home oven lacks a moisture dial. You can't turn it up or down directly. It’s like a car without a gas pedal- to control its speed you'd have to toss sand in the gears, or bolt on square tires, or drag your feet on the ground. So we barely give humidity another thought. Or, we think about it but follow pointlessly comforting rituals. Like trying to adjust humidity by throwing a few ice cubes in a tray before baking bread, or by spritzing water in the oven like air freshener, or by cracking the door open or closed. But how many of these steps are really effective, and how many are merely window dressing? We'll consider two examples- baking bread and water pans in the barbecue. Bakers know that a crispy crust and a elastic texture results from injecting steam in the oven during the initial few minutes of baking. Steam prevents the uncooked bread's surface from prematurely forming a hard "bark", so the bread can rise without constraint. With greater "loft" comes a larger loaf and a more open texture. Steam accelerates browning by exposing hydrated gluten to the hot oven air for the Maillard reaction to kick in.

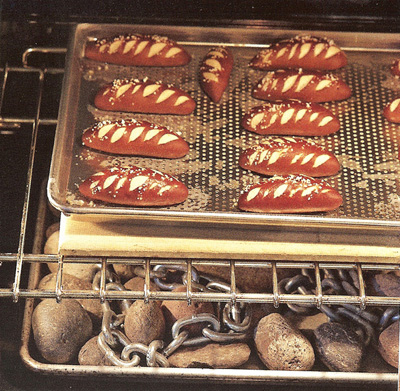

The great Bouchon Bakery, owned by Michelin three star chef Thomas Keller, takes steam seriously. He and executive pastry chef Sebastien Rouxel insert a pan filled with stones and chains into the bottom of an oven. Heat for an hour. Then, just after sliding in the dough tray, they inject water over the stones with toy spray gun.

How much moisture can air “hold”? Well, if we replaced every single air molecule in a 450F oven with a water molecule, which is to say, converted air to pure steam, a cubic foot of steam weighs around 0.5 oz. A 2’x2.5’x1.5’ oven contains around 8 cubic feet of air, or 4 oz. of water at 100% humidity and 450F. If we simply poured a half cup of water onto a hot baking tray, a portion will flash into steam immediately, but this evaporation will cool the tray, and a pool of water would remain. This pool will take much longer to evaporate. Not very effective, and likely to sog out the crust. Instead, we squirt water into a tray filled with rocks and a steel chain. These varied shapes greatly increase the surface area, and the substantial mass stores a ton of energy. And we need a "ton". To immediately convert 4 oz of water to steam, a lot of hot mass has to give up its stored energy to the water, and a lot of surface area is required so all the water is in intimate contact with a hot surface. We also wouldn't want to cut things too close- instead of exactly a half cup of water, perhaps 3 times as much water (12 oz) and more stored energy in the rocks and chain, to make sure the steam lasts a minute or so to do its job. How much mass is easy to calculate: First, you must heat water up from room temperature to the steam point, 212F. The calculation is simple, but since America’s melting pot extends to its measurement system, it requires a blend of metric and imperial units: Each gram of water takes 4.2 Joules of energy to rise one degree C. 75F to 212F is around 75C, and 12 oz. of water is around 350 gms. Thus it takes 4.2 J/gm-C x 75C x 350gms=100 KJoules of energy to heat 12 ozs. of water from room temperature to just below steam temperature. Then the hot water has to be converted to steam. Ripping apart the bonds that hold water molecules together into a liquid takes a surprising amount of energy. Called the “latent heat of evaporation”, it takes about 2200 J/gm. For 350 gms, this is 800 KJoules. Amazingly, the energy needed to heat water from room temperature to just below steaming, is an eighth of the amount required to advance one more degree into steam! So to flash evaporate 12 oz. of water we require 900kJ of energy. This energy is transferred out of the hot rocks and metal chain that was pre-heated to 400F (200C), into the water, and thence into steam. Heat capacity determines the ratio between heat input and temperature rise, and varies by material. The heat capacity of steel is around 0.5 J/gm-C, and stone around 0.8 J/gm-C. Let’s average and call it 0.7 J/gm-C. Assume the stones and chain, after flashing water into steam, drop from oven temp down to steam temp (e.g. a reduction of 100C). So 900KJ is released by the 100C drop if the mass was 900 KJ /(100C x 0.7 J/gm-C)=10 kilograms. Or 22 lbs of steel and stone! So our calculation implies 12 oz of water, and 20 lbs of hot mass are needed to fill a bread oven with steam. How does this compare with Bouchon’s recommendation?

Thus cooking, even in a three star restaurant, really is kitchen science after all. How effective do you think spritzing water into the oven, or dropping a handful of ice cubes1 into a tray is, compared to Bouchon's herculean approach?

Some bakers raise the local humidity levels by placing very wet dough in a sealed dutch oven. Which works, for a limited palate of breads. But if you are a serious bread baker, it's time to take a trip to your neighborhood hardware store. And quarry. What about your barbecue smoker2? Humidity will increase the thickness of the smoke ring. Promote tenderness by accelerating the conversion of collagen to gelatin. Prevent the pellicle from drying out, and so improve smoke adhesion. Maintaining a high humidity level is one key to successful smoking. You can increase LOCAL humidity levels by placing your meat in an aluminum foil tray filled with evaporating pan juices- the high walls of the tray prevent humid air from blowing away. But it does block smoke. Or, you can constantly mop or spritz the meat. Which will interfere with bark formation. Usually a smoker incorporates a water pan somewhere between the fire and the meat, so you can smoke and humidify simultaneously. Does the water pan actually increase the humidity, or are you fooling yourself? It all depends on where you place the water pan, and how much air is flowing past the meat. In an electric smoker, the hot wire elements generate very little heat compared to a wood fire. Consequently, electric smokers tend to be well sealed with tiny vents, so precious hot air is not squandered. By measuring airflow out of a vent with a hand-held anemometer, and the machine's dimensions, you can estimate how often the entire volume of the smoker is exchanged. Which turns out to be a few times an hour. In a big offset smoker where the firebox is directly connected to the cooking chamber, high airflow is necessary to maintain combustion. The entire volume of the smoker might turn over once a minute! And in a coal grill or ceramic cooker, we can measure the air exchange directly, or simply note external fan controllers (like the BBQGuru) are rated at around 5 c.f.m. Thus, if your Weber grill is around 5 cubic feet in volume, this controller implies 60 air exchanges an hour. Now imagine you want to maintain a humidity level of 10%3. Which is 10% of 2 oz/cu ft (pure steam ar 225F). The electric smoker is very humid. They are typically 2-4 cu ft in volume and exchange air 3 times an hour. So they require 3 cu ft *3 changes/hr *0.1 oz/cu ft= 1 oz/hour water evaporation. Much more reasonable. A 12 lb brisket will lose 25% of its initial weight during a 10 hour cook, or around 5 oz./hour. So the meat juices alone will keep the smoker air moist. Some barrel cookers maintain 10 exchanges an hour. So they might JUST keep themselves humid. Though a water pan is helpful. But, in a 5 cu ft smoker with 60 air exchanges an hour, this means 5 cu ft * 60 exchanges/ hr * 0.1 oz/ cu ft= 30 oz of water an hour. Or 4 cups. So unless your water pan is consuming 4 cups of water an hour, it's unlikely your humidity level is very high. Even more challenging is a big offset smoker of 20 or 40 cu ft volume. In a larger smoker, if you want to increase humidity levels, then the pan should be right above the fire so it is close to boiling. And, you can increase the surface area for evaporation by filling the pan with lava stones immersed about half way into the water. They act like tiny sponges or radiators, and can increase evaporation rates by more than 50%. But generally, if you are not evaporating a few cups of water an hour, the air isn't very humid in a big rig.

So what have we learned?

|

||||||||||||||||||||

|

-------------------------------------------------------------------------------------------------------- 1 Ice cubes have to melt before they heat up and turn to steam. So, in exchange for the convenience of tossing solid water into the oven, it takes an additional 330 J/gm of "heat of fusion" to melt ice, or another 100 KJ for 12 ozs. 2 Measuring humidity levels in a hot, smoky environment is problematic. Most sensors fail in seconds. Their electronics short, their windows fog, or their motors seize up. I've built devices which last for a while, but it takes significant mechanical and electrical skills. Which is why I am emphasizing water consumption rate vs air exchange. Unfortunately, while you can buy an accurate digital thermometer for under $100, an accurate and robust oven humidity meter presently cost thousands. However, I have experimented with a digital humidity meter (carefully protected by a hepafilter so the sensor is not contaminated by smoke). The sensor was mounted in the center of a MAK 1 pellet smoker on a cool Fall day. The humidity level varies widely as the smoker is turned on, water is added to pans resting on the heat spreader, and meat is placed on the grills:

(Air at 100% humidity and 225F contains ~600 gm/m3of water, or ~2 oz/ft3) Interestingly, the 40% ambient relative humidity would drop to 0.5% in a 225F kitchen oven- e.g. the same amount of water per volume present in the kitchen air, just hotter. In a smoker, without meat or a water pan, the initial humidity is 1-2%. This higher level is a result of moisture released when burning the pellets, as well as residual moisture from ashes and creosote. Some barbecue pits that are rarely cleaned reach even higher humidity levels. 3 Why 10% humidity in a smoker? Well, when meat cooks, moisture is constantly evaporating. A 12 lb brisket will lose 20% of its initial weight in the first five hours, or around 7 oz./hour. If the water pan is producing less moisture than this, why bother? You are not producing enough water pressure outside the meat to slow down its own evaporation. On the upper end, when you tightly wrap meat in aluminum foil, the humidity rises to nearly 100%. This drops evaporation to near zero, and the extra humidity helps tenderize the collagen. But it is also very aggressive- too early in the cook, and steam will overcook the surface leaving the interior was still raw. And remove flavor. So the 10% number is compromise. Enough humidity to slow drying, but not enough to wash out smoke, stop the bark from forming, or outrun the diffusion of heat deep into the food. It is also higher than even the most humid of summer afternoons. On a sultry, nearly intolerable day of 90 degrees and 90% relative humidity, air contains around 0.1 oz of water/cu ft (30 gm/m3). Compared to 2 oz/ft3 for steam. So it is true outside humidity can affect how your food cooks, but only on days when sweating doesn't make you feel more comfortable. The rest of the time, your smoker or oven is bone dry.

|

||||||||||||||||||||

Contact Greg Blonder by email here - Modified Genuine Ideas, LLC. |